Email: [email protected]

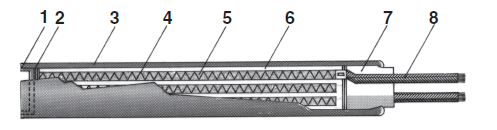

- Heliarc welded end seal.

- Mica.

- Series 300 stainless steel sheath of precision dimensions and tolerances for intimate, stable, non-oxidizing contact with cavities machined for them.

- Element wire situated in close proximity to outside surface for maximum heat transfer and minimum internal temperature while preserving good dielectric qualities.

- Magnesium oxide packing.

- Ceramic element support.

- Ceramic cap.

- Teflon insulated leads: 1 ⁄4″ diameter Fiberglass leads: 5 ⁄16″ – 3 ⁄4″ diameter Post terminals: 15⁄16″ – 23 ⁄8″

• Hotwatt Precision Cartridge Heaters provided localized heat to

restricted work areas requiring close thermal control. Dies,

platens, and a variety of other types of processing equipment are

efficiently heated. Closely controlled work temperatures up to

1250ºF are obtained by a combination of heater location and

proper wattage output.

• Basic designs are readily adaptable to a wide variety of special

requirements, sizes, or ratings.

• Maximum surface temperatures up to 1250º F.

• Designations are etched on the sheath to preserve accurate

shape.

• Heating elements arranged just beneath outside surface for

maximum heat transfer, minimum core temperature and faster

heating.

• Made in U.S.A.

• Where specified, units can be supplied liquid tight.

• Long, trouble free service.